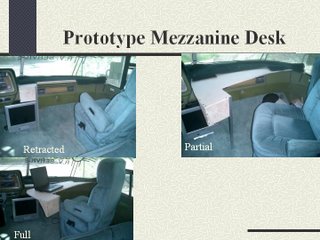

Passenger Seat Desk

The least used space in the GMC has always been the Passenger Seat area. On the road and while we are camped I have always wanted a flat desk and a place to work that did not take up the table or living area.

Gene Ransom, once told me he built a swing-out desk for his wife to work on while they were traveling. So with that idea, I have started on my Mezzanine desk.

Here are the beginning pictures of the prototype of this desk. I have used it on two trips (one to Casa ) and it has worked very well.

To see the work in progress, look here

http://tinyurl.com/r5qs4

The plan was to implement the following features:

1 Flat dash while running down the road for feet and navigation computer (no more sliding off of the dash)

2 Power station to provide (I hate cables all over)

12 volts

110 inverter

110 shore power

5 volt Ipod power

USB ports

Cable Storage

Cell phone storage

Audio plug (Ipod)

3 Slide away under the Dash Mat

4 Hard surface that will match the table and dash for for writing,computing and food

5 Can be used sitting straight or at 90 degrees

6 Will not interfere with the engine hatch cover

7 Will not interfere with the TV / DVD player

8 Desk can be removed, it is attached by blocks in the slot behind the windshield. (pix to follow)

9 Drink holder

The idea is that this desk will not be visible in the retracted position. The Dash will now be flat so the co-pilot can put her feet up there or work on projects. No longer will I have to clean off my computer, printer, manuals, antennas, etc while we are camped. I now have my own space where I can get on free WIFI at 4AM from the campground..... priceless.

Well, there is more to come, but I thought you might like to see what I showed at the Casa rally ;>)